Bricks are one of the oldest and most commonly used building materials. They are versatile, durable, and have a range of properties and types suitable for various construction needs.

Properties of Bricks

1. Strength:

- Compressive Strength: Bricks should have high compressive strength to withstand heavy loads. Typically, this ranges from 3.5 to 35 MPa, depending on the type.

- Tensile Strength: Bricks generally have low tensile strength, which is why they are often reinforced with other materials.

2. Durability:

- Bricks are resistant to weathering, including freeze-thaw cycles, making them suitable for various climates.

- Properly fired bricks have low water absorption, which enhances durability.

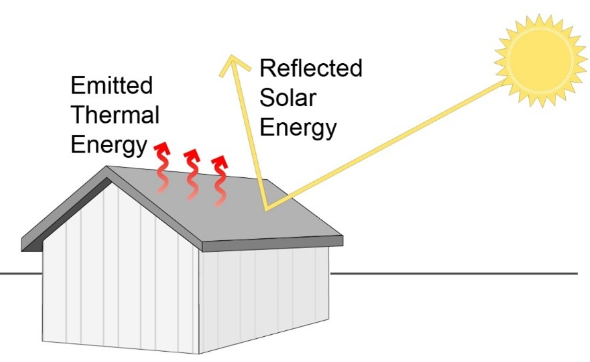

3. Thermal Insulation:

- Bricks provide good thermal insulation, helping maintain stable indoor temperatures. This property can vary depending on the type and density of the brick.

4. Fire Resistance:

- Bricks are highly fire-resistant due to their composition, making them a safe choice for construction.

5. Sound Insulation:

- The density and mass of bricks make them effective at sound insulation, reducing noise transmission between walls.

6. Dimensional Stability:

- Bricks maintain their shape and size over time, which is essential for maintaining the structural integrity of buildings.

7. Aesthetic Appeal:

- Bricks come in various colors, textures, and sizes, allowing for aesthetic flexibility in architectural design.

8. Efflorescence:

- Bricks may sometimes exhibit efflorescence, a white crystalline deposit on the surface, caused by the movement of water-soluble salts.

Types of Bricks

1. Clay Bricks:

- Burnt Clay Bricks: The most common type, used for general construction. They are durable and available in different grades.

- Fly Ash Bricks: Made from fly ash, cement, and sand. They have a uniform shape and size, are eco-friendly, and offer good strength.

- Fire Bricks: Also known as refractory bricks, these are made to withstand high temperatures, typically used in kilns, fireplaces, and furnaces.

2. Concrete Bricks:

- Made from cement and aggregate, they are strong and durable, often used in facades, fences, and as decorative elements.

3. Engineering Bricks:

- Known for their high strength and low water absorption, they are used in structural applications where strength and durability are paramount.

4. Sand Lime Bricks:

- Made from a mixture of sand, lime, and fly ash, these bricks are known for their uniform shape, smooth finish, and high compressive strength.

5. Perforated Bricks:

- These bricks have holes or perforations that reduce their weight and improve thermal insulation. They are often used in partitions and non-load-bearing walls.

6. Hollow Bricks:

- Hollow bricks are lighter and provide better insulation properties. They are used in modern construction, especially for partition walls.

7. Facing Bricks:

- These are high-quality bricks used on the exterior of buildings for aesthetic purposes. They are available in various colors and finishes.

8. Acid Resistant Bricks:

- Made from materials resistant to chemical reactions, these bricks are used in environments exposed to acids and chemicals, such as laboratories and industrial plants.

Each type of brick has specific properties that make it suitable for particular construction applications, whether for load-bearing structures, insulation, or decorative purposes.

.png)

.png)